-

Content Count

49 -

Joined

-

Last visited

Posts posted by 408WPN

-

-

2 hours ago, BGDAV said:Is it a t56 magnum? Pretty sure u can flip the thing around back to front , I run the forward position on mine

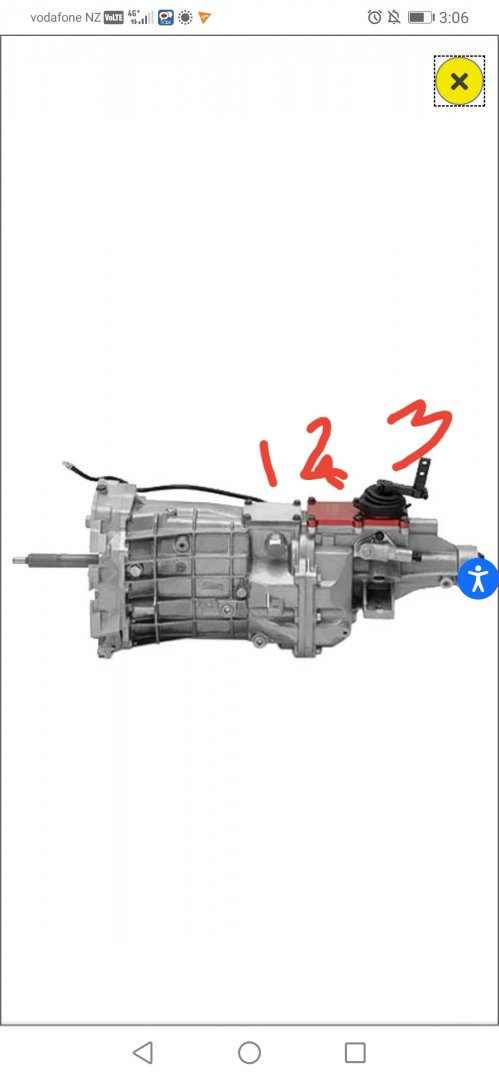

Yeah #2-3 shifter location can swap around but was concerned about #1 shifter position but found dimensions of TKX and measured it out & I'm swt as.

Got a good score on a XD centre console with rubber boot for $40, apparently over here just the rubber boot sells for $80 alone.

It's chopped & I'm gonna have to Chop it some more but happy.

It's sucks when ya press return key one too many times & loose everything that just typed out

-

On 8/22/2021 at 11:00 PM, BGDAV said:Yep that’s the one you need , the Ford stuff doesn’t work for the bore size needed for the slave cylinder - need custom mount but it’s all doable

Hey BGDAV, aren't I clever, I managed to quote my own post

Hey um... did you have to change your shifter location 1 2 or 3.

Hope I don't have to use #1 shifter location, it's $455 USD for a mid shifter.

I'll fork out for that if I have to as want to keep my bench seat

-

On 8/22/2021 at 10:13 PM, BGDAV said:i had a brief read over - I've got a 408 with a t56 mangun and hydraulic clutch, go hydrualic if you can, but its costly exercise, I don't use any of the standard gear but the hydraulic pedal box - better flywheel, FC holden master cylc (standard ford isn't enough even bored out) custom mounts, custom pedal stop (must do this or you'll blow out the seals on the slave cylc - I did it sucks) tilton throw out bearing (slave) i used malwood, and dellow slaves both leaked, pay the money once and do it right, tilton was self adjusting no spacer bull s*** all built into the design was a threaded shaft - solved all my problems- sounds like you have power similar to mine - its costly but now its all perfect

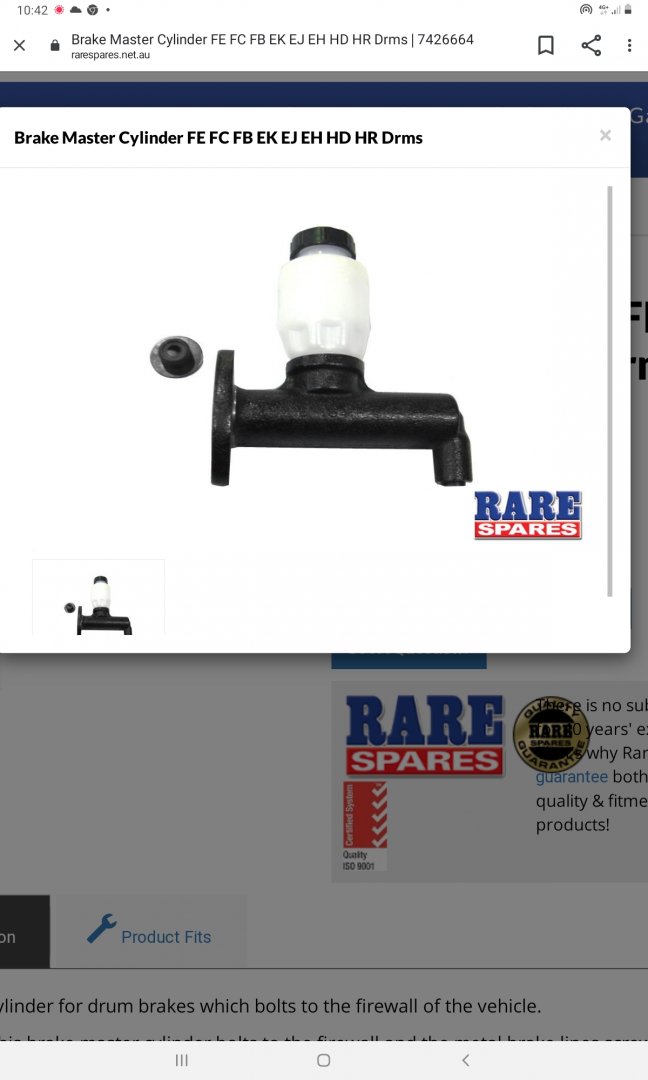

Hey just reading over this, is the XE brake booster & brake master still OK to use, it's just clutch master needs to be a FC HOLDEN... I understand why now it's about the bloody bore size

-

1 minute ago, Thom said:This is something I've seen before, some heads the holes for the screw in studs is exposed to the intake ports, so it is possible if there is no thread sealer on the rocker studs that the engine could be sucking oil in around them, as far as setting valve lash goes there are some good videos about it, but it is something if you are not sure of its worthwhile having some else do it or show you how

Thanks so much

NZ Be back to level 3 on Wednesday, so hopefully bit closer to getting it sorted

-

1 minute ago, deankdx said:yeah i hear you, been happening here for 25yrs that i know of.

there are a few switched on people on this forum, but its' still hard to work out on the internet.

unless @Thom has any input or can tag someone else. i can't remember what engine it is already other than it's possibly windsor based?

Cheers Dean, apreciate

deankxf reacted to this

deankxf reacted to this -

12 minutes ago, deankdx said:seeing you aren't a mechanic, or know enough to risk touching it yourself(i'd be hesitant, and i have 20% of a clue)

ask them if they have an authorised mechanic in NZ you can send it to for confirmation.

if they don't find a local TRUSTED mechanic, and get them to approve him to work on it? or ask his opinion (i'd be asking an engine builder/reconditioner to do it)

Yeah I've touched base with blueprint myself & they seemed happy enough to do it myself but no way hozay.

If it went paired shaped, good chance it'd void my warranty & kiss goodbye to that.

Silvester performance V8's down in Christchurch 350km away is who imported the engine in,I contacted them & they reassured me they were going to email Blueprint engines & pretty disappointed to learn Blueprint haven't heard from them.

Been stung by a few mechanics in last 12mths ,not listening to instructions & mainly over charging etc so plenty of trust issues there. There is local guy here that seems pretty clued up on V8 Fords

My main hope listing on forum is hopefully engine builder see's it & can comment about rocker stud threads etc & whether this be contributing factor to the problem

-

Hi everyone

Crappie raining day in Picton NZ

Too much time over thinking etc

Last year bought a XF ute un-certed, originally rebuilt stroked 393w, that went South.

Breifly considered rebuild but for some bizzare reason had a sudden rush of blood to the head & went down the track of 408ci crate engine from Blueprint engines in USA with a 30mth warranty.

Few months later all certified & on the road, happy days. Done break in as required & have also used manufacturers recommended 10w-30 mineral oil.

About 6wks later checked the oil & noticed I'd used about a litre, thought, hell that's not good but put it down to, I don't know what

Topped it up, kinda forgot about it, checked it again last week had used all of the top up & now discoloured. All of this & have only done about 1800km..

Jumped on another forum, some suggested try different oil grade such 20w-50 high zinc.

Now down to the nitty gritty & this is where I need the advice on.

I've been in touch with Blue engines & have lodged warranty file etc.

They seem to think when the heads where getting assembled they've forgotten to seal the rocker stud threads & this could be the cause of the problem but 2L oil in 1800km is a bloody lot.

They seem to think it's an easy fix, easy to check for, want the rocker studs removed & forward on photo's of the threads.

Well it's not bloody as easy to check for is it, such as removing the studs x 16 & then torque'n them back into place, then also adding such technical terms in place such '0 lash 3/4 of a turn (((that's after bolting them back into 40 lb torque, they're also screwed in & not pressed)))

Also been advised by a freind have to rotate engine so opposite cylinder is rocking when removing studs, worst case scenario if undoing it wrong, motor will go bang

.

.

Really after just dribbling on about all this,, has anyone heard if this could be the problem & why would it use so much oil. On a positive note it's note blowing blue smoke & I've got a 30mth warranty but they cover there arse's big time in the small print but have been really good so far in saying they'll look after me

-

1 minute ago, jca25 said:Thanks have sourced Xe hydraulic pedal box, should do the job

jca25 and deankxf reacted to this

jca25 and deankxf reacted to this -

Just now, BGDAV said:Yep that’s the one you need , the Ford stuff doesn’t work for the bore size needed for the slave cylinder - need custom mount but it’s all doable

Thanks, just when ever but no hurry could you send me photos of custom mounts & pedal to please, cheers

-

31 minutes ago, BGDAV said:i had a brief read over - I've got a 408 with a t56 mangun and hydraulic clutch, go hydrualic if you can, but its costly exercise, I don't use any of the standard gear but the hydraulic pedal box - better flywheel, FC holden master cylc (standard ford isn't enough even bored out) custom mounts, custom pedal stop (must do this or you'll blow out the seals on the slave cylc - I did it sucks) tilton throw out bearing (slave) i used malwood, and dellow slaves both leaked, pay the money once and do it right, tilton was self adjusting no spacer bull s*** all built into the design was a threaded shaft - solved all my problems- sounds like you have power similar to mine - its costly but now its all perfect

Is this what slave cylinder on FC looks like,abit gay looking, possibly cause holden part, also tilton throw bearing probably different part number for your T56 compared to T5 WC

-

8 minutes ago, BGDAV said:i had a brief read over - I've got a 408 with a t56 mangun and hydraulic clutch, go hydrualic if you can, but its costly exercise, I don't use any of the standard gear but the hydraulic pedal box - better flywheel, FC holden master cylc (standard ford isn't enough even bored out) custom mounts, custom pedal stop (must do this or you'll blow out the seals on the slave cylc - I did it sucks) tilton throw out bearing (slave) i used malwood, and dellow slaves both leaked, pay the money once and do it right, tilton was self adjusting no spacer bull s*** all built into the design was a threaded shaft - solved all my problems- sounds like you have power similar to mine - its costly but now its all perfect

Awesome thanks for the tips, comes in very handy  & also Google the Tilton bearing, good stuff

-

5 hours ago, gerg said: -

-

6 minutes ago, deankdx said:what's the rev range of the engine(cam being the main thing)

with 3.23 ratio in the diff, it's probably only doing 2600-2700 at 100kmh, this isn't terrible and is what the manual (4 speed) XEs had with a 351 from memory.

if your cam/engine combo only revs to say 6500rpm then it probably makes bucket loads of torque at idle and may suit a 2.92 diff ratio. (only brings revs down to 2300 ish at 100kmh though.)

i'd just live with it as is. if it's working well, and a good combo it's probably not worth changing for overdrive

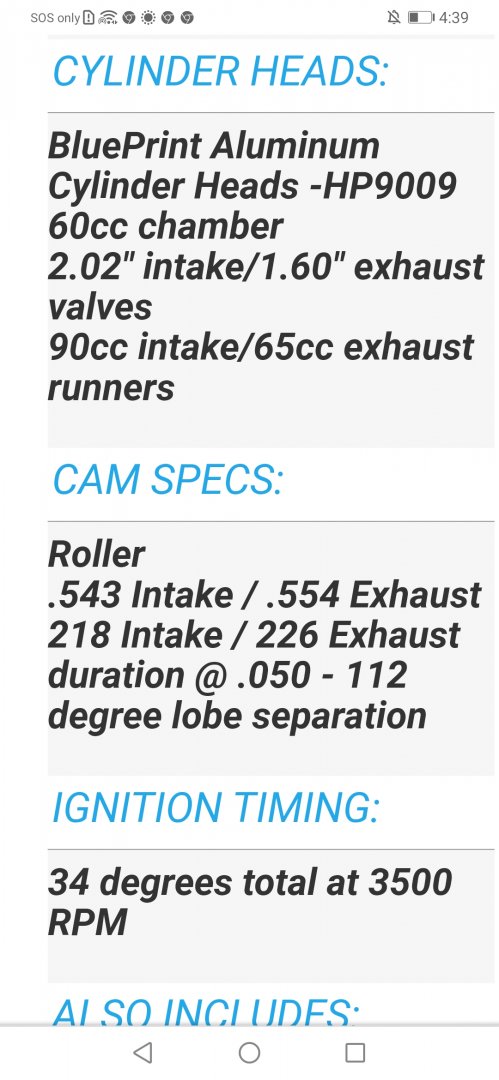

Yeah not sure on rev range etc but have added a pic of cam specs.

-

38 minutes ago, gerg said:Ok I'll chime in, I did a T5 conversion a few years back and firstly I think my 6 cyl box is marginal behind even my mild 302. Unless yours is a T5Z, (specially made Ford high-torque version), you will make it go pop pretty quickly behind a 408 stroker. My money is on 3rd gear.

To go hydraulic, you need the longer pedal shaft that pivots the brake and clutch pedals. I managed to swap mine without swapping the pedal box, but I had to cut a little corner off the heater box to get it in. I still would rather do that than swap a pedal box.

The cable type pedal pivots on its own one that sits lower in the pedal box, normally a spot-welded plate and pin that goes in a punched hole in the LH side of the box. I converted an EF to manual by making up a pivot out of a gal bolt and bolting it through that hole with large washers each side. You will need more than this though, as I found out it was starting to crack the pedal box from the stress. I made up an extra brace that went from the other side of the pedal down to the firewall, bracing both sides. This worked fine until I got rid of the car.

You can go cable on a V8, but you need a V8 cable bellhousing which I believe were only made in 157 tooth flywheel size, ie 302 Mustangs. Seeing as yours is based on a 351W, it will be 164 tooth, and will require a bellhousing to suit that. I don't think any 351s were ever cable (any F-truck experts here?) so I think your only option is to go hydraulic. Unless there is a way of fitting a 157 tooth flywheel with the right imbalance. Early ones were 28 Oz, later (post 82) were 50.

Next is slave cylinder clearance. I have Tri-Ys on mine (I believe Genies or similar) and I had problems with the clutch line fitting coming in from below hitting one of the pipes. I just swapped the fitting and bleed nipple around so the fitting is up top, bleed is on the bottom. How do you get the air out you ask? Just pump it up, push the slave cylinder all the way back in, which pushes the air back up to the reservoir and then keep pumping pedal/pushing cylinder back till you get all the air out. Works fine for me. The bleed nipple is only there to plug the hole.

I researched this countless times to come up with the cheapest/simplest way, I seriously looked at cable (as I didn't want to stuff around with pedal boxes) and I did go hydraulic in the end.

Sent from my CPH1920 using Tapatalk

Thanks to you both for the excellent feedback & now you alone could of saved me thousands & obviously made my wife happy & saved myself countless head in hands, thinking "F" this.

Shall I chime on in with my amateur hour input.

The T5 did have a Z in it F4ZR,the flywheel tooth count differently sounds familiar, the T5 had 300 lb of torque rating my motor 470 lb but some advice I got ther, was as long as I'm not doing massive burn outs or thrashing it changing down it would have been OK

probably not

probably not

.

.

My tri-y's kinda looked like heaps of clearance cause quite low (I'll add a photo )

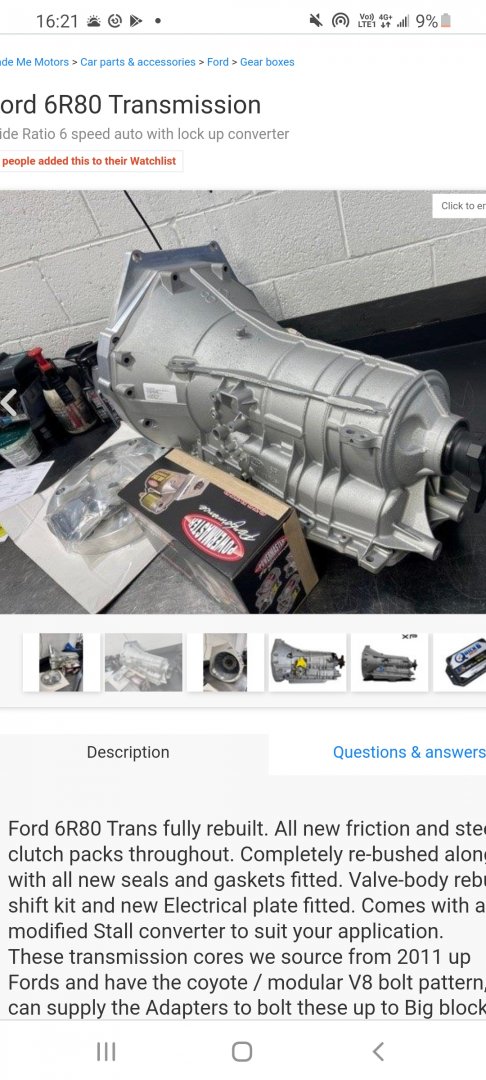

At present just got rebuilt Fmx but just feel I want some form of overdrive, AOD transmission out of the question & on Trademe there's another Transmission Ford 6R80 6 speed that they've adapted to be bolt onto SBF.

Can't really afford latest Tremec TKX ,emailed place in USA for complete package in clutch etc, came to $8300 nzd if that's not including GST when lands in NZ.

Then the whole Hydraulic vs cable dilemma would arise again & obviously hydraulic is the way.

Manual fun all day long but even just some form of something moving on from 3spd & suppose diff ratio comes into play also, which is 8" 3.23

All so added couple pic's of Ford 6R80

thanks again for the invaluable feedback

gerg reacted to this

gerg reacted to this -

16 minutes ago, deankdx said:as fun as a manual is, i'd rather keep a working setup on the road. especially with lots of variables in a conversion like this.

that's about all i can help you with on it, @gerg might have a little more to add on the clutch side of things

if it's set up for cable clutch i'd use it. the pedal box is a cable one.. so reinforce it behind the pin like mine(remove the plastic bush near welding or be very quick to cool it with water as you weld) reinforce the firewall also.

you will probably need an XG clutch cable (unleaded XF) maybe EB falcon clutch cable .. to be long enough i'd probably measure the length before buying it as the 3 i mentioned are probably all slightly different, and all for 6cyls maybe the EB V8 one or XH V8 one is longer.. check it (leaded XF and XD XE have forks on the drivers side, way too short)i like the way is says, "in very good condition as you can see in photos" hard to see INSIDE a gearbox like that.

primo M8,so much great advice to come back to when needed.

Bloke with T5 list lot's of photos of cogs etc but end of day wouldn't know until running

-

2 minutes ago, deankdx said:as fun as a manual is, i'd rather keep a working setup on the road. especially with lots of variables in a conversion like this.

that's about all i can help you with on it, @gerg might have a little more to add on the clutch side of things

if it's set up for cable clutch i'd use it. the pedal box is a cable one.. so reinforce it behind the pin like mine(remove the plastic bush near welding or be very quick to cool it with water as you weld) reinforce the firewall also.

you will probably need an XG clutch cable (unleaded XF) maybe EB falcon clutch cable .. to be long enough i'd probably measure the length before buying it as the 3 i mentioned are probably all slightly different, and all for 6cyls maybe the EB V8 one or XH V8 one is longer.. check it (leaded XF and XD XE have forks on the drivers side, way too short)i like the way is says, "in very good condition as you can see in photos" hard to see INSIDE a gearbox like that.

Thanks a million great help, best I've had all day researching I've done.

If I can get my engine issues sorted under warranty, will be able to buy the T5.

Can you search SandyAndy Wilson on messenger & flick us a message

-

45 minutes ago, deankdx said:for Me, i'd use whats there.. as long as it can handle what your 408 is going to put out hp wise

it works depending on what clutch you've fitted i would guess.

do you have a bell housing for the gearbox? if it's cable, i'd consider just using it.

finding a hydaulic pedal set up for XA-XE (fits XF) is usually difficult or expensive. you can convert it naturally with lots of mucking around.

the slave set up you'd be mucking around a fair bit also, you can use a CONCENTRIC slave inside the bell housing again, well depend on heaps of stuff, what fits, what bell housing etc etccable pedal boxes from XF are weak, they crack at the pivot pin with a standard 6cyl clutch even eventually..

same for the firewall where the cable goes through..

you can reinforce both prior and see how you go.. or leave it and try it for a few weeks etc seeing if it even works well enough.

this (was fully welded later) was how i reinforced My pedal box

ignoring the rust in this picture bodged with fibreglass.. that's how an XE clutch master is reinforced.. the XF is basically flat panel with a tube off it.

you can reinforce the front to make a stronger cable mount(they do crack the firewall also with standard 6cyl clutches eventually)

Bloke I'm looking at buying pedal box off out off XE 6 but seems to think XE 6 pedal box same as XE 8 & could of adapted hydraulic set up to fit.

That doesn't matter though as long as XE pedal box strong but photo's you added of reinforced area are awesome.

Going to add some photos & T5 looking at buying.

Have got some problems on the new crate motor have to sort out first, is under warranty but gone through about 2 l oil last 1800km

-

Hi looking at Manual conversion on my XF FALCON UTE 408w.

Have opportunity to purchase MUSTANG 93 T5 wc V8 gearbox.

Seems alot of people prefer to go hydraulic over cable due to reliability over cheaper set up with cable.

Have done quite abit of research & seems 8 out of 10 prefer hydraulic.

Cable set up alot stiffer on leg etc if sitting at intersection & could be prone to stretching or snapping.

Headers on my motor are Pacemaker

tri-y's & hang quite low so not sure if hydraulic slave cylinder or bracket would get in the way also.

Can't remember if this references hydraulic or cable but also read possible for firewall damage or pedal box twisting etc

Any feedback be great thanks

Rpm concerns on new purchase

in Cleveland

Posted

Hey Guy's

Howz it.. Touching base to query some excessive RPM on New buy I'm in the final stages of.

87 XF Fairmont Ghia 408c, race car spec's on the new engine build, running a strong C4 trans & 8 3/4" 3.25 ratio diff but doing 4000 rpm at 100k.

That kinda sounds like it sucks, what you reackon