-

Content Count

5,202 -

Joined

-

Last visited

-

Days Won

86

Posts posted by Outback Jack

-

-

Never tried that Ford Man, I use wet and dry so I can start off about 400 grit, then 600 grit , then 800 grit.an alternative to wet&dry to smooth the deck is a combonation stone, I recently brought my bro a new one for work (mechanic),

I get them cheaper through my work, Norton/Bear large (230mmx80mm) silicon carbide stone.

I probably don't apply enough pressure when sanding, but like to go on the cautious side.

I'd still like to use an MLS gasket but the last one cost me $450 and it left a bad taste in my mouth having to throw it because it was toast.

I'm not sure I can get the finish it requires.

Sent from my S21 using Tapatalk

gerg reacted to this -

Yeah my factory gasket has lasted a fair while but I maintain my cars pretty well.Nice write-up there Jack. I think your factory one may have lasted as long as it did due to less heating/cooling cycles throughout those km travelled, being a country car and all. Most suburban/city cars would have their head gasket let go anywhere from 150k to 250k.

It also helps if you keep the cooling system up to scratch and never let it cook. As little as one instance of overheating and the damage is done (warped head, broken head bolt, corroded bolt and/or surrounding gasket).

In my EF, once I was stuck in traffic on the Cahill Expressway (coming onto Harbour bridge) and the radiator tank exploded. I pulled up immediately but I think somehow the fans didn't come on before that. So that made it run hot and boil over/blow a radiator.

Another time, I blew a heater hose on the M7 going to work without knowing, and only found out I'd run it dry when I pulled up at the bottom of the exit ramp with the engine locking up. I managed to cool it back down while running back and forth to a nearby creek to get some water. I tried putting some in and it was that hot, it boiled straight back out at me. Once I finally got some water in it, I heard an audible "click" and I reckon that was a head bolt snapping. From that point on, the motor just didn't have the same pep it used to, and it used coolant fairly quickly.

An all-iron motor would have none of these issues... A major downside of running an alloy head and iron block together, coupled with the fact that these heads are pretty big, amplifying the expansion difference between the metals.

I can see why Ford finally went with an MLS gasket. They let the two metals "slide" over each other as one expands in relation to the other, while still managing to seal.

Sent from my CPH1920 using Tapatalk

Always checking for leaks etc, regular servicing, quality lubricants and filters.

Country driving helps.

Ford went the MLS route for just that reason. They raised the compression on the AU motor, so it was a logical step.

The MLS gaskets are better at sealing 2 different metals like Alloy and Steel.

They can handle detonation better and resist 'lift' by the alloy head at operating temps.

I would be using one if the block finish was better, but block sanding is not machining and I don't want to create an uneven surface.

Sent from my S21 using Tapatalk

gerg reacted to this -

OK, just thought I would put this up for people who were looking at replacing the head gasket on their 4L SOHC motor.

There are a few different head gaskets available for the 4L.

From left to right are....

(Left) Endurotec Composite head gasket with silicon embossed seals.

(Centre) Permaseal Composite head gasket.

(Right) Permaseal AU style Multi Layer Steel head gasket with Viton coating.

The 4L SOHC motor from EA-EL come from the factory with a Composite style head gasket.

This has steel fire rings around the bore holes and a steel inner layer sandwiched between 2 composite layers.

This can also have silicon sealing rings to help with sealing water jackets , oil galleys etc as with this Endurotec Composite head gasket....

The 4L SOHC motor in the AU came from the factory with a Multi Layer Steel (MLS) style head gasket.

This is an aftermarket Permaseal AU style MLS head gasket.....

This is usually 3-5 layers of stainless steel with embossing around all the ports and a rubber/viton layer to help with sealing.

Now it is common practice for people to replace the older style factory Composite head gaskets on EA-EL with the AU style Multi Layer Steel (MLS) head gaskets.

This will increase compression on the EA-EL motors as the gasket is thinner and can increase head gasket life and strength for boosted applications.

Now if you are rebuilding an engine and have had the head and block faces machined, it's a no brainer.

Switch to the AU style Multi Layer Steel head gasket.

Just make sure you mention to the machinists you want the faces of the head and block to suit, as the MLS head gaskets require a much smoother surface on both faces for correct sealing.

Usually 15Ra-50Ra (up to MAX of 70Ra)

Blocking the surfaces may not even be enough to get a smooth enough surface.

Also try to avoid any sealants, install dry.

The coating on the MLS needs to be able to seal by itself and expand and contract with the steel it is bonded to.

But what happens if your not able to machine both surfaces?

What happens if the head is machined but not the block?

What if you have fire ring marks or corrosion marks/low spots?

Chances are you won't be able to get the required finish to run an MLS head gasket and get it to seal properly without machining the head and block to suit.

MLS gaskets are less forgiving of surface imperfections.

This is a block that needed a head gasket replacing. It has been block sanded already, but as you can see, there are still imperfections in the surface.

These include Fire ring marks and Corrosion marks.

The block is super smooth but has imperfections.

But not to fear.....

While machining of the block and head would be the ideal thing to do for a perfect finish, it's not always possible.

I suggest at LEAST the head should be machined.......

And the block then block sanded with fine wet and dry, a lubricant and alternating between 45 degrees one way, then 45 degrees the opposite way with a Large sanding block.

Composite head gaskets are a lot more forgiving than Multi Layered Steel head gaskets when it comes to surface finish.

They can better seal imperfections in the mating surfaces.

They require 30Ra-110Ra, which is a much rougher and wider range.

Composite head gaskets with silicon sealing rings can give help with dodgy water port sealing.

This doesn't mean you can just slap them in. Good surface preparation is still required.

Composite head gaskets can also hold boost up to about 20psi, so don't worry too much about using them on most N/A applications.

Better to have a head gasket that seals properly and works than a fancy one that can't because of imperfect mating surfaces.

This is what happens to an MLS head gasket if installed on too rough a finish.....

That was a Permaseal MLS-R head gasket, less than 500km old.

Installed by a 'mechanic'.

Also if installing a Permaseal MLS-R head gasket to an EA-EL motor, check the rivet on the rear of the gasket doesn't foul and get stuck between the head and block.....

The permaseal MLS-R has rather large rivets, the one on the rear will foul. The permaseal MLS has smaller rivets but I would still check the clearance.

Just a couple of things to keep in mind if deciding to go the MLS route.

I could install another MLS head gasket but chances are it would fail again due to surface roughness.

My Composite head gasket lasted 300,000km from the factory before it failed, so if installed properly it will last.

I will leave the MLS until everything is machined properly to suit it on the next rebuild......

Happy Head Gasketing!

Outback Jack.

-

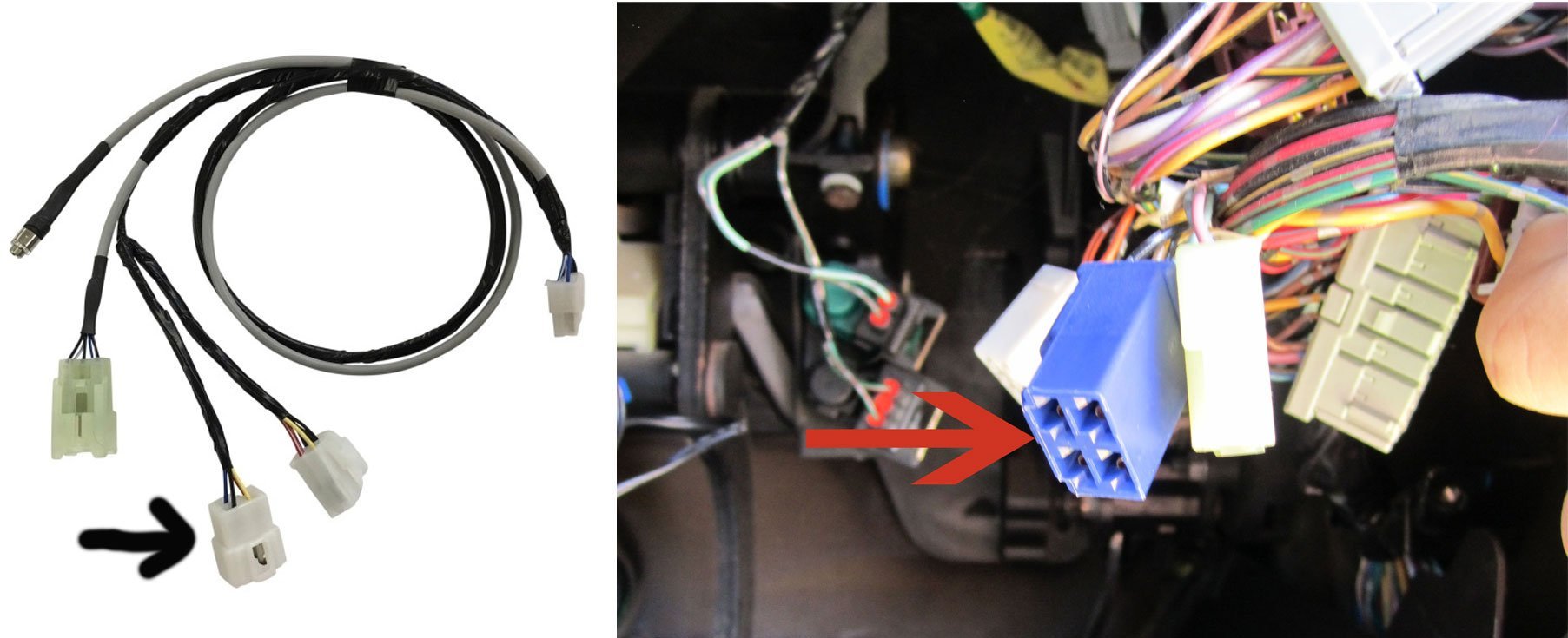

Where you have power to that wiring must be a constant 12V. You want power from a source that only has power when you are running. Switched 12V.So basically, I installed the FALCON BA/BF - TERRITORY SX/SY AUDIO BOOSTER from ASL Media, everything is fine, the audio is 10x better so im happy, the day after my car battery is dead. I then buy a new battery and sure enough the thing is dead in less than 24 hours later. I then realise it is the Audio Booster causing this so I remove it and everything is fine again. If you dont know, the way this is installed is by plugging a female adapter into the blue male plug behind the fuze box of a BF falcon, So if anyone has any ideas on how this issue can be resolved I will love to see your replies so I can get my music back to a good quality. Thanks guys.

Photo of the plug:

So after the ignition and a power source that only powered in the ON position on Ignition barrel.

Try power antenna, cigarette lighter, an amp power on from head unit.

Just a few.

Sent from my S21 using Tapatalk

-

Well hope it all goes ok, and she's rwc'ed without any problems.

Going to be a sweet ride.

Sent from my S21 using Tapatalkgerg and Free.51 reacted to this -

Awesome Free!, nice quick response on the carby.

Getting closer to rego, bet your excited.

Well done.

Sent from my S21 using TapatalkFree.51 reacted to this -

-

Tomato..tomatoe..Stroked 1300 that is

Sent from my S21 using Tapatalk

-

Your loss.Pinto is good for 120-150hp stockish.

No pinto.

Radiator shroud has to be modified to drop a pinto in, because they are too long for a Mk1 engine bay. So even Mk1 RS2000s, from factory had the radiator shroud cut out, so the radiator could sit further forward.

you're a little light on the figures. a 4 door is 840kg.

So, any engine upgrade will be a 1600.

a 1600, with a mild cam, some head work, 32/36 carby, headers, will make a comfortable 70-80kw at the flywheel. which is about double what it currently has. considering i can get the 1300 to rip skids easily, and i can get it to power slide as it is, a 1600 with double the power is going to be more than enough fun.

eventually with a 5 speed box behind it, it would be perfect to drive on the open road.

2door like mine was closer to 700kg.

I had 250rwhp.

The radiator mods are very minor, can do it with tin snips.

I pulled the 1300 and had the 2L in and running in 1/2 a day, by myself.

Was silly how easy it was to bolt in.

1600's are ok, but its just a bored 1300 in the end.

But if that's what your happy with, enjoy.

Sent from my S21 using Tapatalk

-

Hey Panko,

2litre pinto time? Engine and gearbox drop straight in. Even a stock 2L is soo much fun in a 700kg MK1.

Tailshaft will need changing , different end to the gearbox and radiator needs to go forward besides that it's a doddle.

I ran a 2L pinto in my MK1 years ago, with a TP1 cam, worked race head and a Holley 350. Beast.

If you roll the guards before it gets painted you can get 13's and 235's under it all the way round.

Was the best thing I ever did to mine.

Sent from my S21 using Tapatalk2redrovers reacted to this -

That sucks Panko, hope you are OK and it's sad to see the lil Escort like that.

With time it will be repaired mate.

Chin up.

Sent from my S21 using Tapatalk -

Hope this helps mate.Can you explain the superheat part ?

I asked all the places in town and even the google machine and never got a straight answer . I ask because there is 2 tx valves available with different properties , I forget which one I got .

when I got the car it had a complete sealed York system on it but the pump was shot , I replaced it with a used xf sanden style pump . It’s all original xseries stuff other than the r12

I did notice that when I charged it , when it cycled on , the low side was only around 15-20 psi at around 2k rpm . Maybe just needs more gas ?

From XF workshop manual.

Sent from my S21 using Tapatalk

-

Yeah mate, it's cost me a packet and still back at square one having to pull head off again and fix it myself.Fucking poor form when they rip off anyone mate, let alone a pensioner. When you don’t have a clue, go to Lew’s

Being a pensioner, I had a budget of 3.5K.

$1800 head and crow cam (quoted)and another $1200 new rims and tyres.

Should of come home with some change in my pocket or at least to budget with extras.

I estimate its cost me about 7K in money and NOS kit all up, plus 2 weeks free labour.

I could of had a completely rebuilt motor for that with all the fruit.

Lesson learnt. I been done by the young fella before years ago, I thought he'd changed....gave him another chance.

Bad decision.

Didn't expect the same from his old man.

And both of them blaming the other for the shite, just playing me.

Sent from my S21 using Tapatalk

-

Ok, here's the skinny on head gaskets.

Normal composite head gaskets on EA-ED and XG.

40nm + 90 degrees.

AU MLS head gasket on EA-ED and XG 30nm+ 120 degrees.

Now on MLS-R head gaskets there are little copper rivets all along the head gasket to keep all the layers together.

Now it's normally OK, the rivets are positioned so they don't foul on the mating surfaces. But like it says in the MLS-R file- Due to differences in head castings etc, it may be necessary to drill out the rivets that foul on the mating surfaces and it's ok to remove them.

This is what the rivet looks like in a position with no fouling...

Now when we put the head on the motor, I bought up to the "mechanic", and I use that term very loosely, that I thought the rivet at the rear of the head looked like it was going to foul.

'Nope, she'll be right' bullshit.

Well as you can see in my last post, there is a leak of some kind at the rear of the head.

On closer inspection, this is what I found on the drivers side rear.....

As you can see the MLS-R head gasket is not sitting flat.

Let's have a closer look.....

Now I'm pretty pissed off, as you can see, it's not sealing properly and there's coolant and oil.

All for the sake of one rivet, and 5 minutes to remove it.

Now I will have to pull the whole head off just to remedy this one pissy problem I paid to have done properly.

And I hadn't named names before, but I bloody will now.

After working 2 weeks for free in their workshop being the coffee making, give a hand on everything workshop bitch, while waiting for the machine shop to get my head back,whilst more than paying my way while staying up there for two weeks, getting gouged on my bill by my so called mate and his father, even after taking care of them.

Spending 5K and getting treated like shit when I question the bill and some labour/ part prices.

And.... for having to fix all their fark ups on my ute after paying good money to get it done properly by people I thought I could trust and would look after me.

Lews Auto Repairs in Bunbury WA.

Wankers!

The only reason other customers don't know they are getting gouged is they don't know what stuff costs and get bullshitted.

My old man was a mechanic and I have worked on cars all my life, so I know what shit costs.

$450 for an MLS-R head gasket that t.i. performance sell retail for $300. Bullshit.

2 weeks work from me there means nothing and worth nothing.

Still paid over a grand in labour, most of which I did myself.

A quoted $1800 head and cam job ends up over 3.5K with me supplying most of the labour and all the gaskets.

And they know I'm a pensioner, didn't stop them at all......

Sent from my S21 using Tapatalk

Searley reacted to this -

Hey guys,

Had my head done a couple months ago, have noticed what looks like a few oil weeps from head gasket...

Passenger side rear....

Drivers side rear.....

And this one up front, but this could be top of timing chain cover...

Now I didn't torque the head down and was surprised when the guy who did , did it in one stage, even questioned it.

'Nah, she'll be right'. That's ok I suppose when it's not your car or your money.

Even had to pay $450 for the head gasket, found later on the bill, that retails at $300.

I have new torque to yield bolts in and am wondering what is the correct torque for a 1.3mm MLS head gasket (this one is permatec MLS-R) on a 4L block?

AND...

Is it possible for me to check/retorque the head bolts without damage?

Seems I paid good money to have things half arsed done, and now I'm going to have to correct it all myself.

Grrrrrr.....

Cheers Fellas.

Sent from my S21 using Tapatalk

-

Cheers Bear, and Gerg and Thom for your input.

Much Appreciated.

I wanted to do the block in my ute as its matching numbers but that will leave me with no transport, so looks like I might have to have the short block in the spares ute done.

Only thing I'm worried about is its been sitting for 9 years without a head on it, under the spare ute bonnet.

Sent from my S21 using Tapatalk -

That's ok mate, its Friday night!Sorry I should have specified .050inches not mm hehe.

hehe.

So that means 020 or twenty thou over should be OK then?

Which would be O.5mm?

I'm confusing myself now, haven't had a Jacks....lol.

Sent from my S21 using Tapatalk

-

Ok Gerg, might have to get the bores machined then....damn, was hoping to avoid that,Hey Jack, 0.2 mm is 0.008", so if you have less than 8 thou wear in the bore (and hopefully it's worn evenly and not barreled or tapered) then 0.2mm would file down to where you need it, albeit with some extra ring tension, but that's with old pistons.

New 0.2 pistons will require some serious honing, not easily done with home garage tools in an accurate way. A shop hone generally takes off the last few thou after the borer has cut the bulk of the meat off.

Sent from my CPH1920 using Tapatalk

Sent from my S21 using Tapatalk

gerg reacted to this -

Yeah and I've had her for 10 years now.Before you got your ute the prev owner must have given it a hard time when cold, from what I've seen thats the best way to kill rings in a 4.0

Hehe.

Did the pics work? Don't for me.

I misread what you said Thom, you said over 0.050 would require machining.

So I guess 0.50 is machine shop time then.

I always get confused on the measurents, so the pistons are 20 thou of an inch over or 0.50mm, correct?

I see what your saying now Gerg.

Excuse my stupid.

Sent from my S21 using Tapatalk

Thom reacted to this -

That's what I was thinking Thom.Anything more than .050 will most likely require a re bore

Be a nice tight fit anyway at 0.50.... take up some of that 300,000km wear....

Hehe.

This was the sticker on the back of the block, head had never been off and shows all bores as Standard, no over sizes.

Head gasket was just about welded to the block after all those kilometers. Lol

Bores weren't bad at all..

So I'm hopeful of a nice hone and new bearings and she'll be apples.

Sent from my S21 using Tapatalk

Thom reacted to this -

These Slugs look soooo nice....

They are the Silvolite ones. Droooool.....

They say available in 020, 040,060 or 0.50, 1.0 and 1.5.

So if I just honed the block would the 020 or 0.50 go in with 0.50 rings ok?

Or am I up for some machining for a stock bore?

Sorry it's been awhile, I'm a bit rusty.

Sent from my S21 using Tapatalk

-

Thanks soo much mate. Legend.The std volume pump is more than adequate for even most extreme builds, considering its a street engine and won't see constant racing conditions the std bearings will be adequate as well if you can find them ef to au have restrictors in the oil galleries to reduce the the amount of oil in the head and keep the bottom end properly lubricated, they just need the oil galleries drilled out to suit them

I did think of just doing pistons and rings with a hone and maybe just chuck a new oil pump and bearings at it to be on the safe side.

I just looked at the ACL race series bearings as I can get both sets for $210.

Which is not bad at all for quality.

The Slugs were the most expensive bit.... $500 for the set but will give me the compression I was after at 5cc dish as I think stock are 7-8cc dish?

Correct me if I'm wrong.

I think the 60 thou off the stock head, AU MLS head gasket and those pistons should get me to around 10-10.5 to 1 easy.n

Hastings rings $128, which are quality too and last.

Now I'm just looking at all the tools I need and extras.

And plastiguage and Vernier calipers to measure it all..... Phew! Never ends...

Sent from my S21 using Tapatalk

-

Hey@Thom ,

Think I have found my combo mate.

Tell me what you think.

Silvolite High Comp Pistons (5cc dish) to suit EA-EL with valve relief cut.

Hasting Rings.

ACL race series Main bearings and Big end bearings.

JP Oil Pump. (Std or High flow)

I have a choice of Standard or High flow oil pump, not sure which to go for and the Big end bearings also come in standard or extra oil.

I take it the high flow pump goes with the extra oil Big End bearings or Standard pump and Standard bearings.

Cheers mate,

Jack.

Sent from my S21 using Tapatalk -

Thanks mate. I will start looking around at aftermarket pistons.The pistons were basically the same for e series au has a smaller dish but a longer rod, im unsure if you can use them in an e series engine you'd have to check if the skirts clear e series counterweights

I'm hoping to find some with less dish or a flat top with valve reliefs cut in.

Just two more questions. The bores when the head was off looked pretty good.

The head had never been off from factory and bores where bang on standard for every cylinder when built at Ford.

If I just re-ring it and hone the bores with new pistons, should I just go standard size rings or go one size up to 0.50mm?

The piston size stays the same I take it.

The only bit that concerns me is the big end bearings and connecting rod bearings. It's been a long time since I have done any of this, and if I replace them I want to do it right, so looks like I need some plasti-guage.

Trying to get all the stuff I need and info before I start.

Thanks mate.

Sent from my S21 using Tapatalk

V8 conversion into a ed and wiring harnesses

in V8 Tech

Posted

Should only have to change the wiring in the engine bay if going from 6 to 8.

May need a few other things, but that's a start.

Sent from my S21 using Tapatalk