-

Content Count

1,608 -

Joined

-

Last visited

-

Days Won

7

Posts posted by FOMOCOHO

-

-

7 minutes ago, Free.51 said:I dont think its the inhibitor switch cos i deliberately put it in drive to start & nothing happened as expected but in P or N it just did 1 tick at a time. The car is home now & ive started it a few times in the drive with no problem........for now

Intermittent fault...It still sounds like the ignition switch could be on the way out if the solenoid checks out ok. XE are prone to failure. I've had one fail on the XE column in my XD. It's still bypassed lol, with a button.

Edit: Makes you feel like you own a GTP when starting it lol.

Free.51 reacted to this

Free.51 reacted to this -

5 minutes ago, deankdx said:yeah, definitely could be inhibitor switch, if so, next time it doesn't start,(assuming in Park), try it in Neutral... and or go from park to 1st a few times on the gear shift and back a few times and try again

Is that a technical term for wriggle tha fucka???

-

I said inhibitor switch failure! By-pass it. What trans is it fmx or C4?

-

I had ignition switch failure. Could be starter solenoid. Remove it and clean, could be dust.

Remember, as Dean says, if you run the two wires, power to the coil still requires the switch so you will need to turn ignition switch ON if you want it to fire otherwise you're just cranking.

-

Ignition switch. Time to find another I dare say... or run two wires to a push button. Other thing could be inhibitor switch on trans... bypass it!

-

-

9 hours ago, XTREME KARTS XF said:EF and EL are different from each other and XH is different again (from what i've been told) I used an XH 6 cylinder one for my XH V8 S Pac (mine doesnt have the fast ratio steering rack like XR models do) Bolted straight in and no issues. They only go on one way as there's flats on each end for the pinch bolt to pass through. You'll be able to do it in about 5 minutes, change it out from underneath the car (thats how i did mine being a V8, 6 cylinders through the engine bay given the amount of room there is) You'll need a hammer, flat blade screw driver (helps with opening up the clamp ends) 10mm spanner or a 3/8 drive ratchet, socket and breaker bar (use the breaker bar/handle first so you dont destory the ratchet mechanism)

Will need a tape measure on a stick too, to reset the toe-in/out if removing the rack-ends. May sound agricultural but it works fine.

-

Can't say I remember seeing that colour but I like it too! Bit reminiscent of 'walnut glow'.

-

Nice!

Is it factory manual?

What wheels was it optioned with - steelies or the Volantes?

Going to put the aircon back on it, with the V8?

Edit -

why does it have an aircon evap, but a non-aircon climate control bezel?

So observant dAVE !!!

SPArKy_Dave reacted to this -

Do these fit an FMX!

Probably but you'd be wasting your dosh... better off spending it chroming the FMX.

My spare already has an air cooled unit...

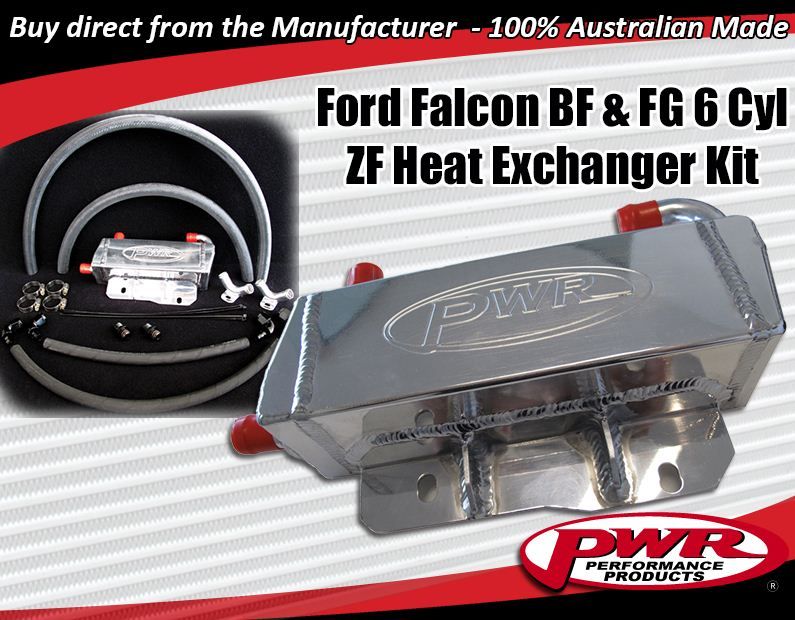

Edit: I'd be more worried about the ZF in your FG-X needing one. Where do they mount the factory unit on the coyote?

-

The mounting position of the PWR unit is better for longtivity. Mounting it on the sump would add to the failure and 'milkshake' mix I think, but may have been done for temperature reasons and not just 'bean-counting' by Ford.

-

Rog, so the ZF's are picky about trans oil temp. Whats it gotta be? around 80-90ºC?

Not sure on exact temp, no gauge so far. Will ask PWR/Ford Tomorrow.

Found this on AFF...

& the link..

http://www.fordforums.com.au/showthread.php?t=11390288

So, according to them the factory unit is sus... Ford will probably say they're fine as would Getrag. I want an independent review!

-

That standed trans cooling setup is very much identical to what Scania and Mercedes Benz buses have with the ZF 9 speed Econo-Life auto boxes. Far as i know they are trouble free. I can only assume that the setup between N/A and Turbo is the same? Maybe ask someone at a Ford dealer maybe?

Cheers Mark & yeah, i'll be talking to Ford local Monday.

-

Can you not just bypass it completely with an external oil to air cooler?

Is your turbo manual or auto???

Edit: this kit is for non-turbo. not sure if kit for FG with turbo & ZF is different.

-

Can you not just bypass it completely with an external oil to air cooler?

No because it would cool the trans-oil too much and then gear selection is affected. Has to be that kit...

Which is expensive...

That's why i'm asking if there is anyone has done it or had any problems with the existing unit. Not spending the doe unless there is leaking of coolant into the transmission issue with the factory units. The ZF trans. is not cheap either, lol.

-

It mounts in a different spot too (on transmission cross-member) if you look at the photo in the ebay link. Maybe for better temperature consistency.

-

Knowing there are plenty on here with an FG with ZF 6-spd for daily I ask the question, has anybody changed the transmission cooler with the PWR equivalent ?

Having done some homework I know how temperature sensitive the ZF is... this appears to be the only option besides the factory unit. It is rather pricey at around $730 for the kit. Questions are...

Is it necessary ?

Is the factory unit prone to leak coolant into the transmission on ZF ??

Has anyone fitted this kit to their car ???

Factory unit on my car...

Kit from PWR...

Ebay example...

-

There were two different types (different suppliers) of the round driving light BTW.

EDit: Can't find the photos yet. Trim code was 'T' on mine... which is same as in add^^^

-

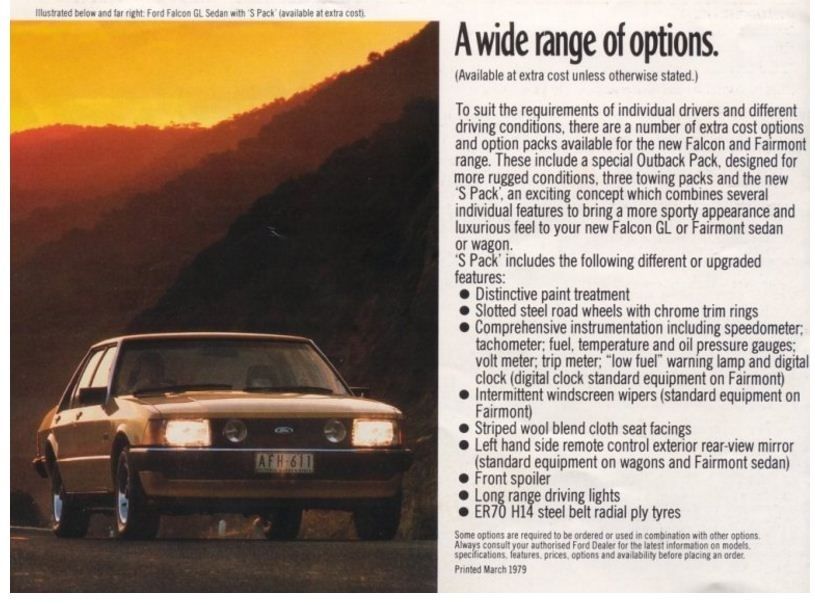

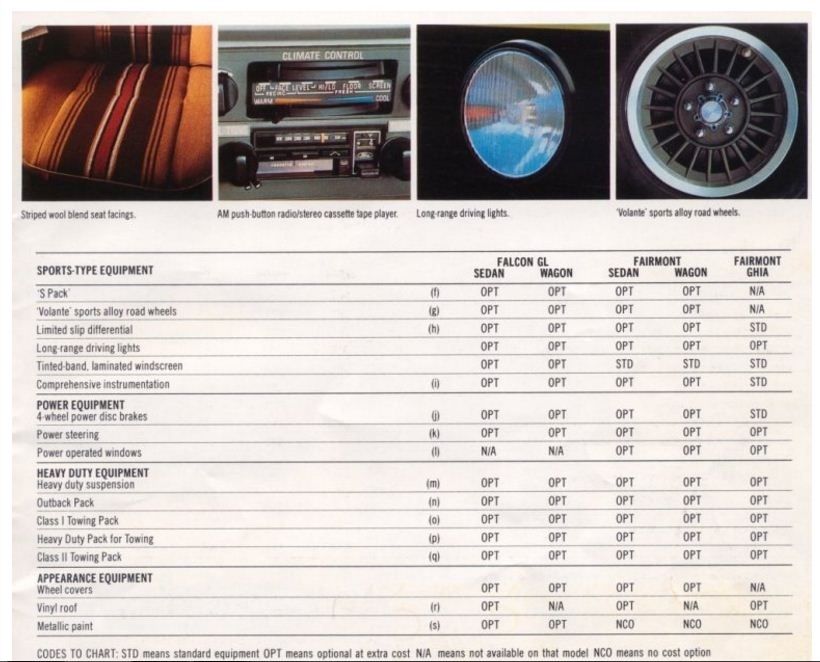

I never new that. Thought GL and S Pac were different models. Cheers for the info

Not until XH. In XH it is a model. Before that it was a GL option.

I think this is why CHESTNUT got confused thinking there was a GLS in the XD range but as Dan pointed out (at the time) it was only late XF utes that were badge-d as GLS,

S pack was really just an option pack on a GL.

What interior code is on the plate on yours?

Good stuff. S-pak was option-48 on GL... like ESP was option-54 on Fairmont Ghia. It will show up on verification if it was optioned. Some parts of S-pak were also available as options on Fairmont etc, like the driving lights and show up on verification with different option number.

-

That is mine, It is actually badged as a GL but got all the S Pac gear from factory. If you want some more photos let me know, Happy to help!

All XD S-pak were badge-d 'FALCON GL'. The 'S' never appeared until XE. My sedan was Burnt Orange... see if I can dig up some photos...

SirkWhyXF reacted to this -

The Arrow block is chinese cast. I don't know that I trust their steel.

Look up the TMeyer Inc. Track Boss Cleveland block.

That's the Tod Buttermore block, finally being put into production.

Yeah, I saw news of the two versions some time ago. I thought the Buttermore version was more trustworthy being made here too.

Cast is cheaper than machining out of a solid billet too!

I think this differential billet was about $6000 from memory, but was some time ago now, scanned from Sandvik propaganda lol.

bear351c reacted to this

bear351c reacted to this -

I've read that originally, the tooling was pretty useless due to the hardness of the Aussie iron, sent everything blunt in no time and they couldn't get the tolerances they needed. That whole line needed a complete revamp before production was feasible.

The higher nickel content gave the Australian Blocks better wear resistance than their American predecessor. Be careful Gerg when comparing hardness to wear resistance, if you think back to your metallurgy days… hardness is a measure of impact resistance only and doesn’t take into account the whole micro-structure of the material so "superior wear resistance" is the term used to be more accurate. Hence shorter tool life.

Basically when the 30x blocks were sent over to re-qualify the tools it was found life expectancy of the boring-tools was much less than they had encountered previously with the American Iron. They tested the iron and found the Australian iron, although with-in spec. was superior by far for wear resistance. I'm sure hardness would have been part of that testing and determined to be higher too. They upgraded to tungsten carbide tooling and that fixed the problem, prior to sending the tooling back here.

A different casting process was used in Geelong than CCP too; which is much more stable.

The drama with the tooling being damaged & having to be sent back initially was a totally unrelated event that happened during shipping.

Ommoht and gerg reacted to this -

What happens if someone should have a Clevo block with a late 73 casting date,

but no engine number?

And normal un-marked rough casting, where an engine number would normally be?

What happens if someone should have a Clevo block with a late 73 casting date,

but no engine number?

And normal un-marked rough casting, where an engine number would normally be?

That's entirely possible. The Cleveland Casting Plant (CCP) had to fill an order for 60 000 blocks for Ford-Aust. before packing up the tooling in late '73. It could well have been one of them if it's here but never made it to production for some reason. Whatever the case CHESTNUT is right, it is of CCP origin.

The cast-tooling and machining-tooling was shipped in '74. The first blocks were cast here in mid '75. Damage to the machining-tooling meant they couldn't be machined until '76. After the machining-tooling was sent back, 30x raw Oz-cast blocks had to be air-freighted back to CCP to re-qualify the machine-tooling before it was all sent back here a second time. Don't know what became of those 30x blocks either! May have come back, may be still there... some-one knows!

Edit: If they did come back, it would have been with the tooling... bet they didn't air-freight them again!

CHESTNUTXE reacted to this

CHESTNUTXE reacted to this -

and my 1982 pillowblock with GF

Just checked the one in my ute and it's stamped 'GF' like yours^^^. Can't see the date or code... starter & manifold & stuff in the way.

Enough banter though... I should be doing other things, doh!

Having some bother with the FD

in Auto Electrics

Posted

I remember you had it out not long ago, did you check the switch condition then? The plastic warps with age and then doesn't make contact in the right places.