-

Content Count

318 -

Joined

-

Last visited

Posts posted by adrianphu123

-

-

If its the dimensions you want, i dont see why not. It has no other function other than to physically be there

-

Hey guys,

Need a bit of assistance with removing the latch mechanism out of the rear doors. I have all the rods disconnected except the latch to door lock bellcrank rod. Any ideas? i dont have enough room to twist the mechanism to get the rod out of either end.

thanks.

adrian

-

-

Hey guys

Got the back windscreen reinstalled after paint with a new rubber and now its leaking from about a 1 inch section on the passenger corner between the glass and the rubber. Windscreen was cleaned around the edge before it was installed.

Any ideas on how to fix this issue?

thanks

adrian.

-

Does anyone know if EA-B-D bumper moulds are the same?

Just saw these on ebay.

-

Thanks guys,

I'll look into it

-

Hey guys,

Just asking what people have used for the red bumper mould strips?

thanks

adrian.

gerg reacted to this -

-

Check your ball joints, I had that problem and ended up being that. Spring saddles also

-

maybe check the interior air vent? it might drop onto the floor when you open the flap by hand

-

Not sure off the top of my head what you're after but this might help you.

-

Hey guys,

Does anyone have part numbers for the bearings in the manual steering box? Looking to rebuild mine but Rarespares don't stock their rebuild kit anymore.

thanks,

adrian

-

I was wondering what that rear bolt hole was for

-

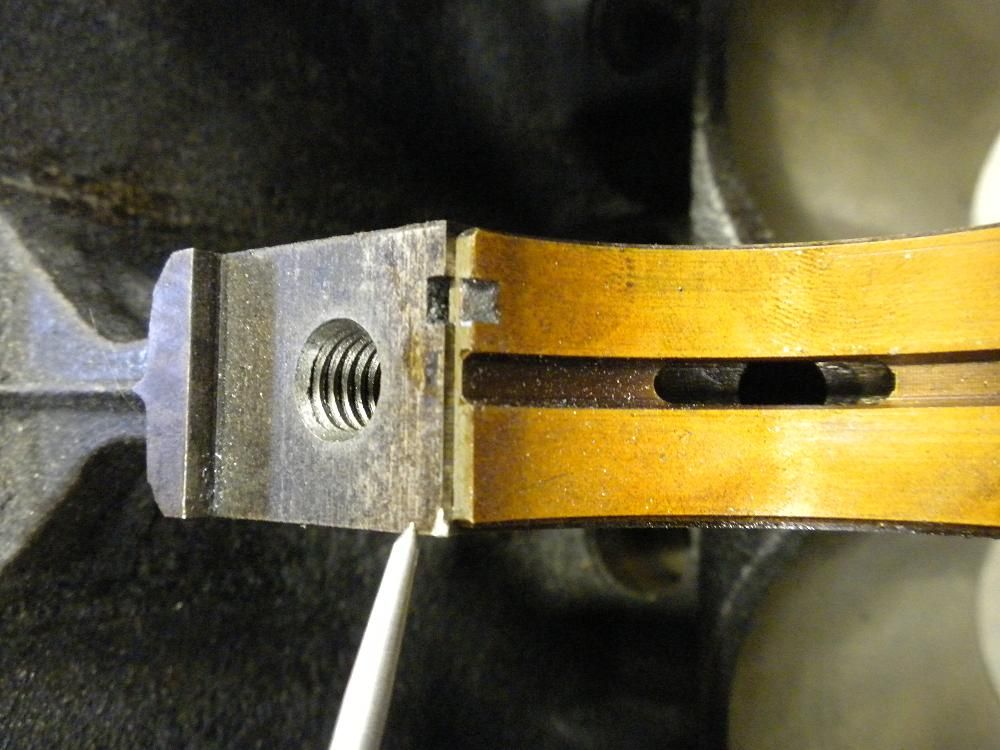

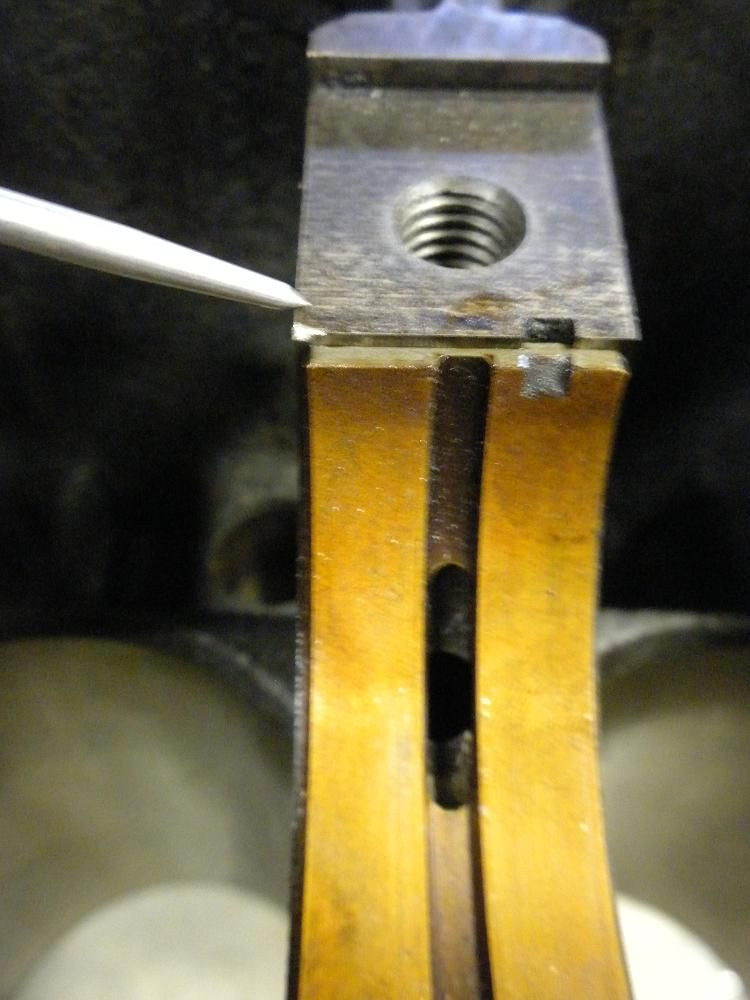

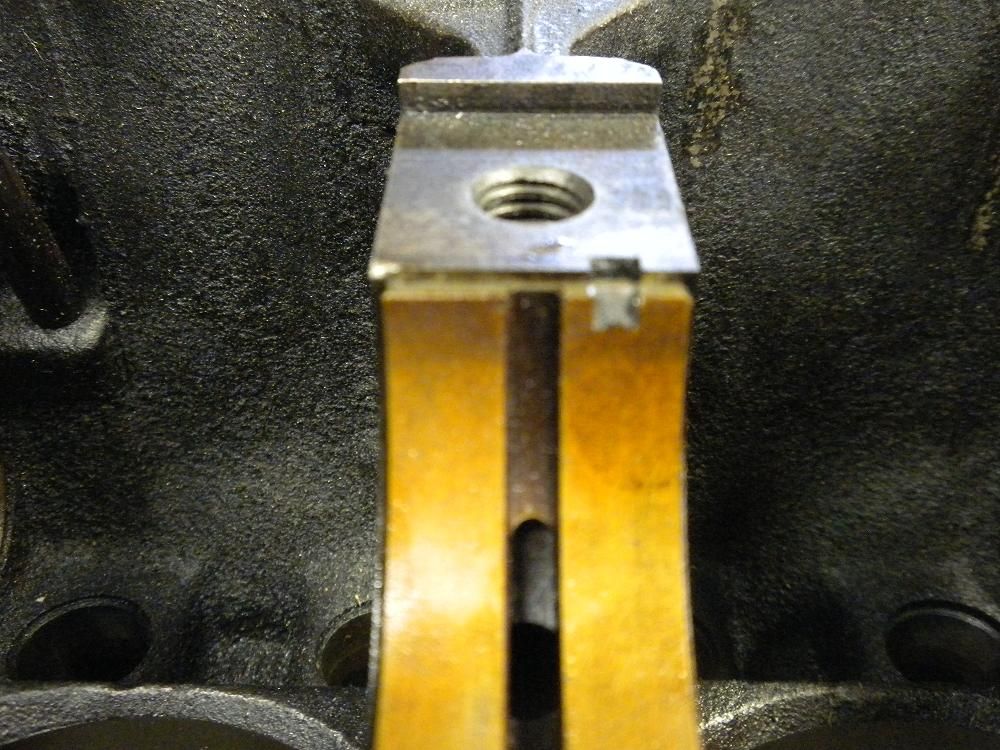

Hey guys,

Bit of a knob today and managed to drop a dolly onto the main cap parting face. Wasnt from high up and just managed to get the corner of it but luckily an old bearing shell took most of it. Just wondering if this is going to cause me any problems.

No material is raised above the parting face and all damage seems to be outbound of the bearing shell (shown with an undamaged bearing shell.

any opinions?

adrian.

-

I agree with needing washers on those bolts, and not spring washers either. As you're tightening them, they'll catch onto the slot and rip the washer apart.

Are those the original bolts? When i did mine, some of the original bolts bottomed out in the hole before even touching the header flange. Go with studs and brass nuts, header install becomes a lot easier

Thom and deankxf reacted to this -

This is how it sits now.

I'll punch louvres over No.4 big end

Whats the best way to control oil movement front and back? Are just straight baffles up and down with holes forward and rear of the pickup adequete?

Any other suggestions or areas to look into?

-

Hey guys,

Has anyone had experience modifying an oil sump for a street car?

On the cards at the moment are increased oil capacity, a windage tray and crank scraper. The windage tray acts a bit like a back baffle but do I need something more substantial?

Any ideas are appreciated.

thanks,

adrian.

-

Most likely front plenum, just in front of the windscreen. Either that or the windscreen itself

bear351c and Outback Jack reacted to this -

I got mine from rocket in Sydney, any brake place should have them or maybe try a place that does hydraulic work

-

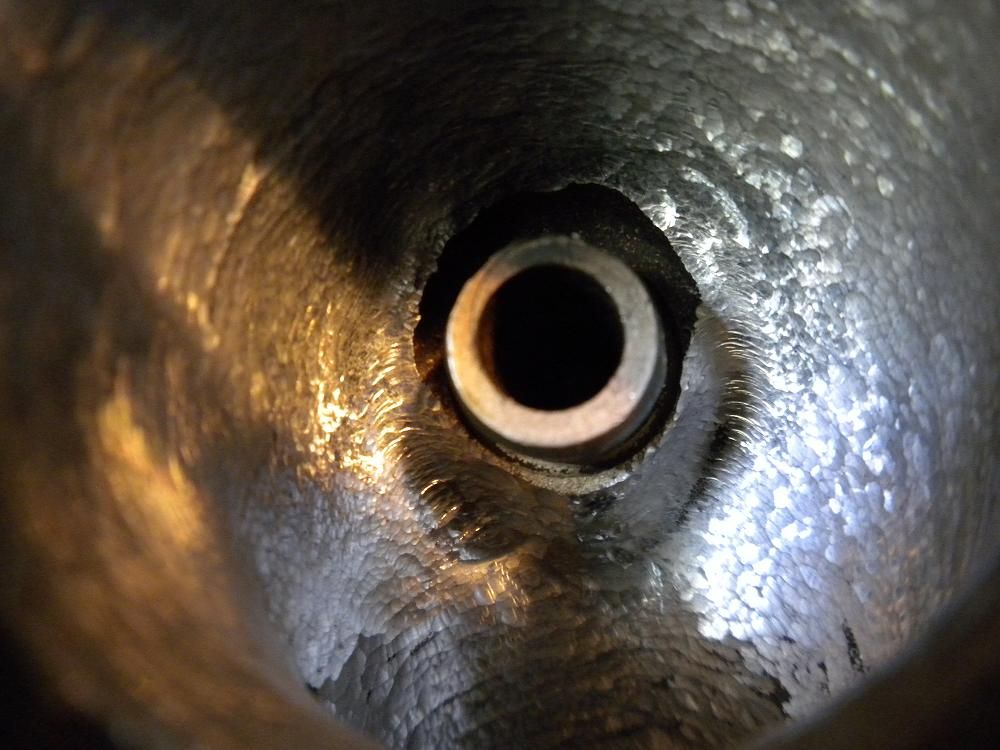

Hey guys, took your suggestions on board and did a bit more work this afternoon. I had trouble getting to the back of the valve guide, i didnt have a burr that would fit so thats next on the list along with some inside calipers.

Ando, the 85-88%, is that for the bowl or the throat?

I made about 3 light passes in the bowl area and did a bit of work around the valve guide. The intake tract and short turn was only textured by the burr using 1 light pass at slow speed.

I also tried to round off the front of the guide boss but i think it still needs more work.

A few questions,

Does it matter if I nick the valve guide?

Do I go to the gasket line on the inlet manifold face?

-

Hey guys, just looking for feedback on 2 inlet ports I roughly ported this afternoon. First time porting so Im sure there are many improvements to be made.

Im practicing for an early unmarked head to suit cam 234 deg @ 50 and 0.550" valve lift.

thanks guys,

adrian.

Outback Jack reacted to this -

considered going manual steering?

-

Just curious, why do you run half a thou more on the mains compared to the rods?

-

i usually run HPR30 20W-60 so 2.5 and 3 sounds the goods. Thanks guys

diff breather bracket

in Steering, Suspension and Brakes

Posted

I think thats just the splash/dust shield for the diff breather, just move the bracket around until the holes line up. Or just throw it out and run without.