gregaust

-

Content Count

343 -

Joined

-

Last visited

Posts posted by gregaust

-

-

Look in behind the shift linkage , the actual year and month is cast there in a round disc. If it is 66 it will be a green dot type valvebody, 67-69 will be the normal PRND21 shift pattern

Yes definitely 24 spline , likely a mustang .

CHESTNUTXE reacted to this -

Only use the 70+ trans . They are better all round. The correct bellhousing is cast iron. You can use that bell on any later trans, only difference if you use a clevo pan fill type case is there will be a flange sticking out around the back of the bellhousing

Look for a trans case , dipstick in case , breather on top of extension housing. Will have the larger 26 spline input shaft, if unsure measure it , will be 0.839" diameteThay are out there although rare

-

302 + 351 are same pistons and from original flat tops . The difference is the shorter stroke 302 uses a longer rod

351 = 3.5" stroke , 5.78" rod

302 = 3" stroke 6.030" rod

SLO247 and gerg reacted to this -

1 hour ago, Valvebouncer said:I'm no Holley expert but I thought the largest 2 barrel carb they make is 500cfm.

Nope . There is bigger

-

Pretty sure they are 3/8 SAE or UNF. I'd have to check the length for you

-

I've done my own . Mower blade bolts are near the same shoulder bolts and come with nylocs and wave washers

gerg and bear351c reacted to this

gerg and bear351c reacted to this -

I will add , just make sure to get a genuine Eaton one . I think there were cheaper chinese knockoffs getting around a while ago.

Thom and xwroo reacted to this -

they mustn't be that good if you've used many of them in the same car haha

Definitely not same car

LOL xwroo reacted to this

LOL xwroo reacted to this -

-

Is it the shape ,,or spline ,, or something that is different on p/s to manual pitman arms ,?

Scored a new one in the box ,, but the part number is rubbed off from being in the cupboard ..

Spline is different

-

Mr XF summed it up nicely. What did you want to know ?

-

Hmmm nah . Usually it will be the other way , P/S box is longer than manual steer so column needs to be shorter . That steering shaft is way shorter

Pretty odd whatever has happened there , either way column needs to be slid out

-

These coil overs look like a nice mod, great for improving handling and adjustable ride height. RRS may seem expensive however the money you spend to setup stock modified suspension properly is not actually cheap either. I have done both, and you will always suffer from shithouse ball joint angles trying to run any decent camber. If you want serious handling you need to cough it up. Just the RRS struts were 3.8 seconds a lap quicker than the stock modified setup, and it handles and rides like my FG. The best thing for me was engineers will sign off on any RRS product with no testing. Plenty of aftermarket options these days out there, which is great for the box models.

I got an RRS setup , works so nice on the track, 1st time i took it out i'm like Yeeees nice !!!!!

Can anyone running these up front comment on how comfortable they are, when set on a softer setting?

Just wondering how good they'd be for comfortable driving in a daily.

A mate has the Vikings in a ZG Fairlane . Ride is excellent , would be fine for a driver . He does a lot of miles .

XFChris reacted to this -

The FMX linkages are on the opposite side to C4, etc.

INCORRECT ... C4 and FMX both on the same side . On the left

-

Well you could go something like a Transgo kit , set up right it can work . The "Race" pressure spring they give you does give around 200 psi pretty easy as vacuum drops.

Another option could be a PTC valvebody . They do an auto shift "ATB" (all time boost), what that does is gives line pressure similar to a manual valvebody as opposed to modulated line pressure .

It does still use a vacuum signal to shift although i seem the remember something that you might be able to run without the vacuum , although i've not tried . Have to check on that .

. I'm using one in one of my own trans seeing plenty of power

It does space the shifts slightly more than a normal valvebody but i like it.

It does space the shifts slightly more than a normal valvebody but i like it. A few other mods it will hold up IMO

-

Did someone call?

What's the reasoning for wanting manual VB? Vacuum for shifts ? or line pressure ?

What's the reasoning for wanting manual VB? Vacuum for shifts ? or line pressure ? A manual valvebody is likely the easiest way , gives full pressure and no dramas with vacuum for shifts . Auto shift can be done although can be tricky to set up , depending on cam size and engine vacuum

Waht's the plans for use ? Street mostly or race only ?

-

XY works fine . I'm using XF rears and big fronts with VE commodore calipers . Careful adjustment of the booster pushrod to have master correctly preloaded. With braided lines the brakes work awesome

-

Just the steering box . You can keep the 16:1 box and fit a manual pitman arm. Then you also need a manual track rod / drag link

-

-

It does matter which way the pickup wires are connected . they are still positive and negative . On the older MSD's which ever way gave the most retarded timing was correct .

On the newer digital stuff it is the other way , most advanced

slydog reacted to this -

It will do fine with the rebuild and shift kit .

Definitely replace the front band , it sees a lot of work . The B servo is ok , fairly small on the apply though. If you can get a hold of an R is nicer or an A will increase apply pressure on the band .

Always replace pump bush and extension bush as they wear the most . The rest as required . Same for thrust washers .

Pay very close attention to the front planet set . A lot of them now are worn out .

You can get by without the kickdown ok . The standard shifters are great , get a bush set for it and they are then nice and firm

MNTL.XD reacted to this -

Sounds like it had had a rebuild . Someone has mixed up the clutches trying to get clearances obviously.

A couple O/S steels that are .092 would get you not too bad . .065 is bit much in the high /reverse , some older factory specs were .050-.070" but no one runs that loose . On 4 frictions i'd be going a max of .040" . 4 will likely do fine , of course 5 would be better but takes a bit of work , there's a few ways around that

If the front band looks ok it could be reused , best way to check is let it relax and open itself up some , look for fine cracks in the friction material .

The 40-2 kit will work nicely , there's a couple options on setup , usually depending on what converter is used etc is how to set that

-

I think the BA diffs are wider ??

-

I'm not a fan of the RRS rear setups . Just way too chunky and untidy for my liking

I used the Struts , brake kit and power Rack , although yes wasn't cheap but was no where near the suggested 20K . I wanted the extra room the struts gave in the engine bay. The added engine bay space saved quite a few $$$ on not having to get custom pipes made , so was a win - win IMO .

I only got the basics I needed . I did not use their pump or lines , again I found them untidy and too blingy as a bolt on

Same for the control arms , WTF ? just pop riveted plates on the bottom

Nor did I use their Radius rods .

Nor did I use their Radius rods .There was a few minor hiccups getting it all fitted up nice but first time on the track , like i said above . I found it did work very nice .

XF347, gerg and slydog reacted to this

XF347, gerg and slydog reacted to this

6cyl c4 casefill

in Transmission and Differential

Posted

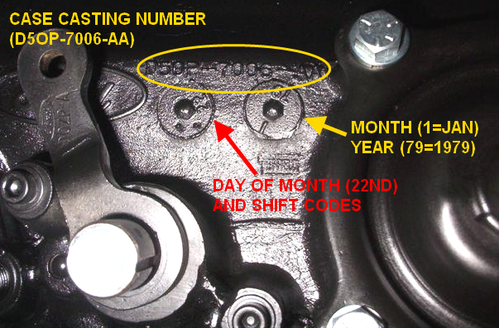

Hmmm a 67 , you should be right . You'd have to drop the pan to check for sure . I could send you a couple PDF files how to tell but basically a select shift will have a C5 casting code on the channel casting, the 67-69 is C7 casting

I believe you are correct on the bells