-

Content Count

1,131 -

Joined

-

Last visited

-

Days Won

6

Posts posted by jca25

-

-

Ahhh, EL brakes...... one of the great mysteries of man kind, LOL.

I have many E-series in the family.

The EL's with ABS, seem to have a somewhat unresponsive brake pedal.

By the same token, the EF wagon project has extremely touchy brakes, so I know the e-series have a fundamental capability, to have good brakes.

I've tried playing with around with my EL wagon, installing stupidly expensive front rotors, and NOS front calipers, etc.

Those things did improve the brakes, but not dramatically.

The EF still has a far more responsive pedal.

I still want to try replacing the booster on my EL wagon, re-build the back brake calipers and fit expensive rotors there too.

It's a learning experience, but I've heard the ABS units can hold air in the system, and need to be operated/pulsed, to force out the air.

This can be achieved by an ABS diagnostic tool, or by test driving the car and standing on the brakes hard, to make the ABS work - then re-bleeding the system.

I personally haven't tested this theory.

Cant say i have had any dramas with the abs units holding air but i have been out of the brake game for yrs now, but one car to watch for is the late model land cruiser the brake master and booster is all in one and need dot 3 only or they stuff up

-

Had this happen in a EF Wagon i had years ago, took me by surprize and im like 'WTF'

Was easy to replace but still a pain in the bum to happen.

Yea we use to keep them and then make one out of two most of the time but they are easy to change over

-

if there is a vac leak the pedal will be hard as to push, u may find the master cyl has die and is bypassing which is common after bleeding the brakes if its not been done before they get a build up of shit in them and when bleeding it the worst thing people do is push it all the way which picks up the shit and kills the the cups. best way to to find out is to pump the pedal up till its firm and then leave Ur foot on it and see if it slowly s goes to the floor

and as to the booster from i can recall they are the same been to many yrs since i play with them

also something to keep a eye out for on the plastic boosters is the case cracks on them have done a few of them

steve mcqueen reacted to this -

lol pro thats wats ment to happen but if the hole is blocked it ends up in the cab

-

Cheers SLO247, they are different, my bad. Sorry JCA.

Jack

All good jack i would of made it work

Jason

Outback Jack reacted to this -

lol yes getting it out is the hard part but well worth it it if you are doing a resto

-

Here is a bit of a rundown on the replacement of the heater core. It was done on an XD so could change slightly between models. I didn't take the photos when i pulled it apart so these are only when it was put back in.

All the screws around the outside need to be undone. It is also stuck together with a sicaflex type glue.

This is the inside of the heater box, there is normally an air con evaporator on the rhs but im not running air con any more so its been pulled out. The heater core just pulls out of the box

The insulator rubber just slips off and on over the top

Note the one pipe that has the curve in it. It needs to go to the top of the heater box when put back in.

While you have it apart you might as well refoam the flaps. I used a 10mm square that i got from spotlight with a spray on glue

When putting it all back together just use a bead of silicone to seal it

JGP, steve mcqueen and Outback Jack reacted to this -

the older days you would kit them but those masters you cant hoan out can only give a light polish unless you want to spend the cash and get it sleved

Outback Jack reacted to this -

Thanks for that i will save it on the compture when i get home from work dont think the boss will like it on theirs lol

-

Go a pbr one any good parts shop will be able to get one in

Ando81 and Outback Jack reacted to this -

Thanks slo247 if u dont mind

-

-

That's to remove the preload on the carrier bearings so you can get the carrier out. All Borgie diffs are that way. The pinion comes out through the back after you pull out the carrier.

You can often pull apart an old diff without the spreader because the bearings are worn and the preload has been lost. Going back together you need it though, the housing needs a couple of thou of preload to be correct. You take your measurements from across the bearing caps using a dial gauge.

Building any integral-carrier diff properly is very time-consuming and most folks just throw them together and they work most of the time.

thanks for that gerg i have always just put them togeather and never had a problem i cant even say i have seen my brother inlaw use one on his race car

gerg reacted to this -

there you go never seen or heard of that before is it only that gear ratio or if u change any of them

-

Could not say can only try them and see jack

-

No problem thanks for trying to him me out

-

cheers mate but its a 351 the ones under the hood is fine i need the ones under the dash i should of put that in my top post

-

Hi guys just like to know if anyone knows where they all plug its been near 8yrs the car has been off road and cant remember where they go so any help would be great

thanks jason

-

I know it sounds funny but try kingswood country they got a bit of ford stuff

NZXD reacted to this -

Hey Guys, what bulbs fit into the high beam of a ELXR8? H1?

ef/el are H1 low beam and H3 high beam

-

A mate here in town done this but with a ba fairmont it looked the part sorry got no pics but i do know it was done with all metal but

-

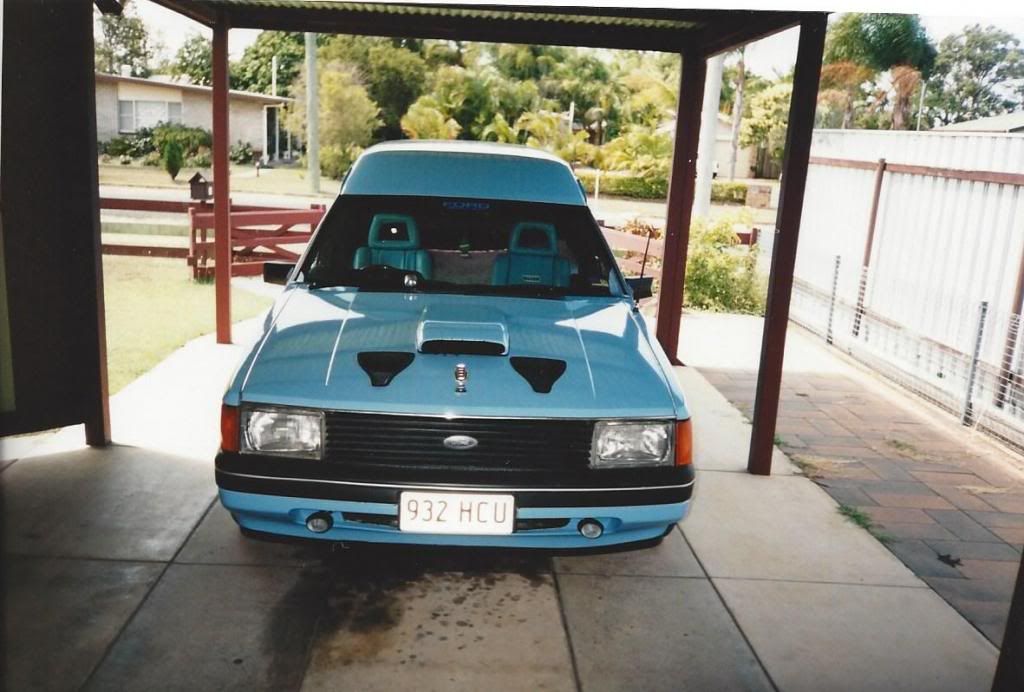

thats a nice van ants u still got her

-

-

While we are on the subject does any one know the difference between the 6 and 8 Tacho in a XCGS?

on the face of the tacho their is a 6 or 8 on it down near the bottom

XD Sedan Radio

in Interior and Car Audio

Posted

My choke in the van the end of the knob was a cover and came off or is mine a diff setup but the hazzard had the white button