-

Content Count

87 -

Joined

-

Last visited

Posts posted by Olive Xm

-

-

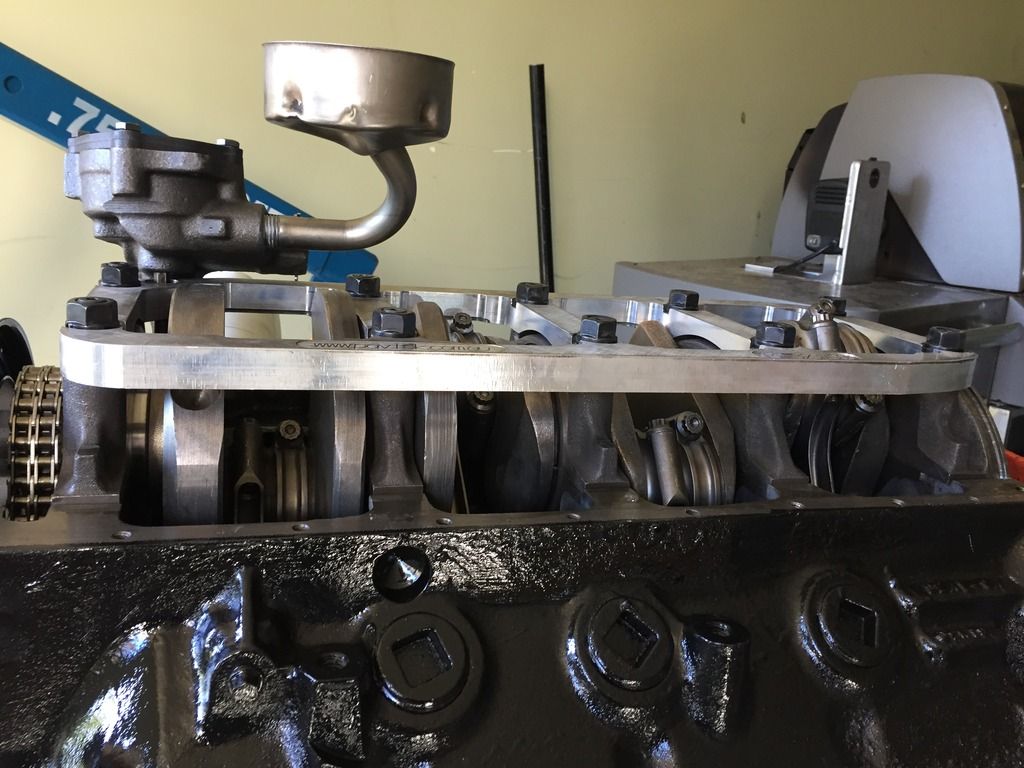

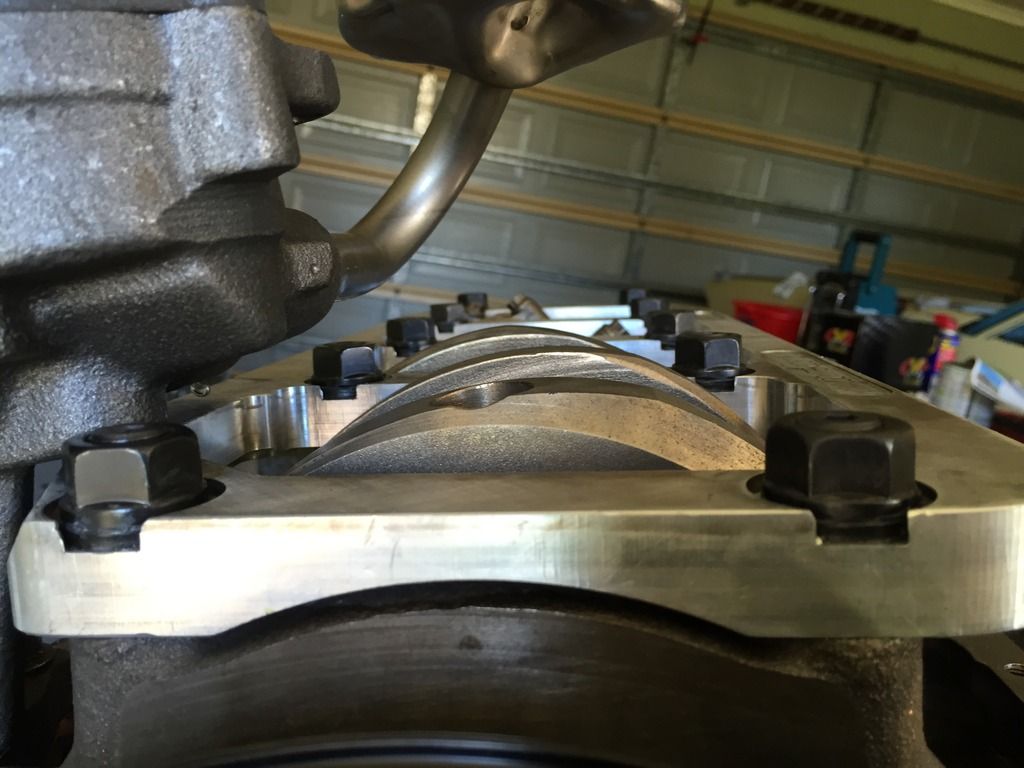

What's wrong with the base plates? I heard they can flex with the HP spring so I installed a second one so it was thicker.

-

You cannot really see too much of them once they are installed as they are in the main webs.

This is not mine as I still have the bottom end together.

-

Yeah one there and one in each of the last four cam bearing feeds.

Pic only shows three thou.

gerg reacted to this -

Hopefully a few are still watching this and I wont have to start a new thread.

Ok earlier this year the engine ate the cam bearings due to what I believe to be low oil pressure, all others were ok and reused. so I sent it off and got them replaced and one piece rear main.

Now I noticed that they did not reinstall the four cam bearing oil restrictors only the one lifter gallery restrictor, I rang them and they said they never use them as the cam pushes down on to the oil holes on the bearing restricting the oil anyway.

Should I reinstall them?

Facts,

Engine is on a stand and the sump is still off.......

I will be running the external oil line and have a High pressure spring in a standard oil pump {Ando76 go easy on me was only running the spring because of all the restrictors}

I was not running the HP spring before.

Low oil pressure was due to low oil level. Sucking in to intake via bottom of intake gaskets not sealing.

Oil returns cleaned up and aligned

Engine has grooved lifter bores.

Now solid roller previously solid flat.

Will be installing drain hoses into rocker covers

Camtech Cam description Rough idle, strong mid range and top end. Modified engines only. Min 11:1 comp ratio, 4.1:1+ diff ratio. RPM RANGE 3200-7000

-

Rod Hadfield dose a drop stub axle that lowers the car and you can run BA front callipers on the std XD-XF discs. All engineered.

stubtech.com.au

-

8k I wont be seeing close to that im running a stock pump that has a high pressure spring. Also has an oil restrictor installed in the driver side lifter gallery.

I looked at that kit and it looks good but I didnt want to pull the engine down that far on this build.

-

Yeah that one has a bit more control around the pickup, nice pan.

-

Well the ones in post 103 are the most accurate that I have, if the flow bench was correct. Duggans use another type and they have to calculate it and they said flow was still increasing after 600" and flowed 340 cfm at 700".

Im just hating that the car wont be ready this year to have a go at this thing.

Trev Vaa reacted to this -

The old cam acted like that anyway so I'm not worried about the idle or the keep it above 2000-2500 factor.

gerg and Trev Vaa reacted to this -

Well it's enough to for now... Lol. I'm just worried I over did the cam, as when I was talking to cam tech they wanted to know flow figures and I quoted the web site.

-

# edited results

Im sure they are right, I just thought it would be closer to the Chi website results. Silly me.

http://www.chiheads.com.au/shop/2v/2v-ford-cleveland/

I asked Chi and they said they have two types of chambers and of coarse I have the lesser flowing one, and they only get the internet results when they do the whole job......

Didn't tell me any of that when I dropped the heads off for the cnc. When I picked them up they said it would probably flow a little bit more.

Kicking myself that I did not get them flowed before.

-

Ok I have some flow figures... on a Superflow @28"

LIFT INT EX TFC

100 65 48 66

200 140 93 144

300 210 134 210

400 270 170 268

450 292 186 276

500 296 195 280

550 296 201 284

600 304 204 288

650 304 204 292

Turns out the figures I had earlier were not off a Superflow, but something else and calculated.

Im not sure on what to make of this.

-

Yeah they used to be very square in the entry, so I smoothed them out and extended them. I will have a look this weekend on how to do the external drains. I don't think that I have the height to drill and tap the head. What size hose ID do you use? I was thinking 1/2" as a min.

-

Rail to floor 213mm and rail to tray 110mm

-

Yeah looked at that but I don't think it will work with my girdle. I was thinking about getting some mesh and attaching it directly across the bottom of the girdle, then with a downward bow in the centre to clear the rods and crank.

The oil returns now line up better and the head gasket holes have been enlarged.

I have Counter sunk the holes in the valley with some deburring.

I am thinking about installing some drains in the rocker covers to drain back to the sump, once I get it back together to see how it will work.

-

The problem I have is getting near the crank with the girdle. I saw in another thread somebody made a crank scraper and screwed it to their girdle, but that was a crossflow I think.

-

Hi Guys, anyone with ideas about how to improve oil control and windage in my setup? After a small issue in the last build i want to improve this one as it will rev a bit higher. Its an ASR pan made to suit The girdle I have and holds 7.5 lts.

Outback Jack reacted to this -

Cool thanks.

-

-

Not enough servos for me, I don't like the thought of getting caught out. Nice to know the one near my work has the "race fuel" thou.

-

Ok, I canned the idea as there are a only a couple of e85 servos around and the engine was for the street.

blownxd393 reacted to this -

Nice, I was thinking about going e85 how do you find it?

-

-

The guys that are doing it are well known for their work.

Melling hv pump.

in Cleveland

Posted

Yeah I went over mine with the surface Grinder.